How to Reduce Friction (All you need to Know): For optimal performance and efficiency, friction on surfaces must be reduced. This can be accomplished in a number of ways, such as by polishing surfaces, lubricating surfaces, using low-friction materials, and maximising surface texture. Enoughinfo.com

Read Also: How To Bypass Reduced Engine Power

We can prolong the life of materials, increase energy efficiency, and maximise the performance of mechanical systems by reducing friction.

All you need to Know on How to Reduce Friction

1. Improve the smoothness of the sliding surfaces.

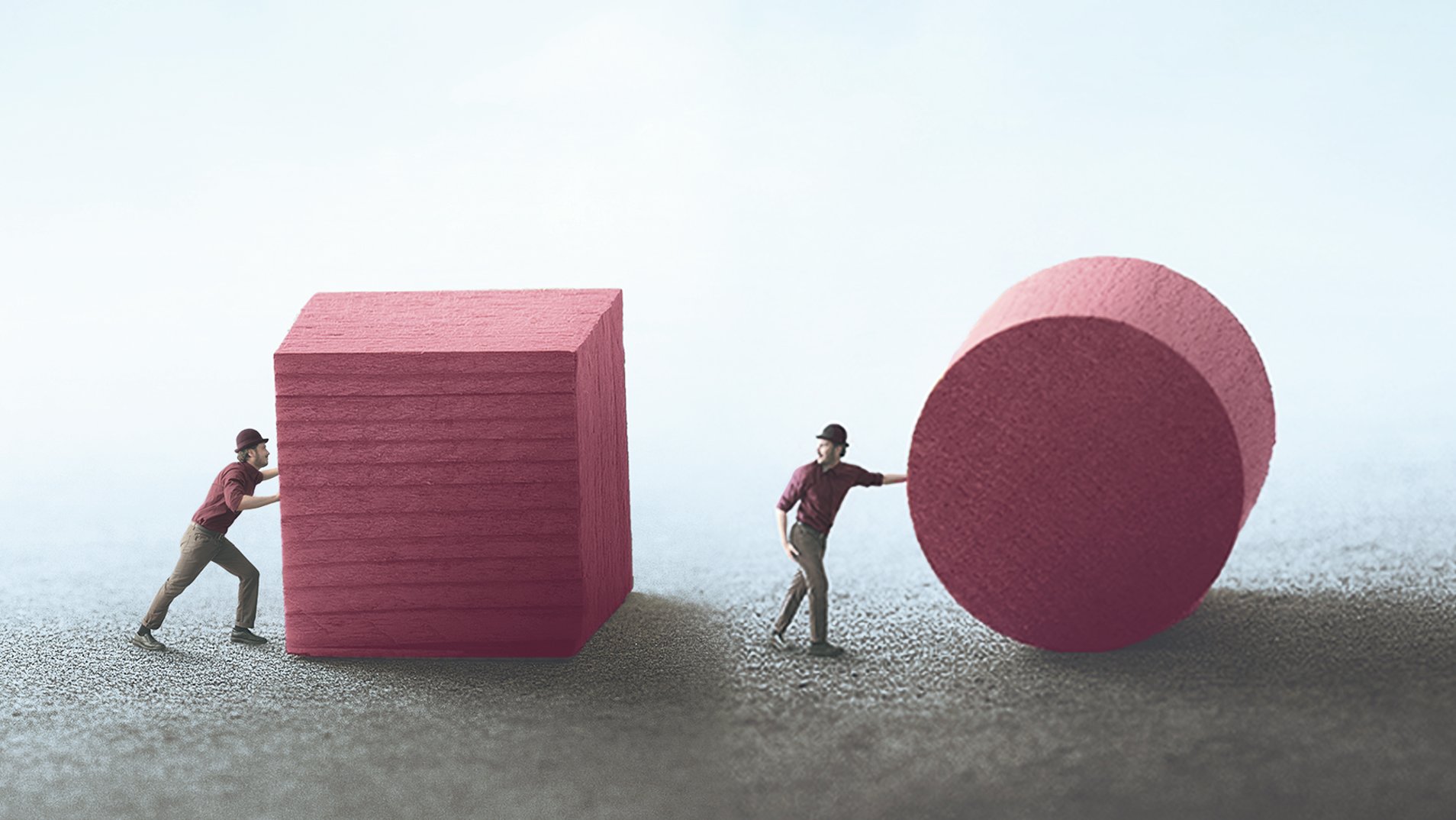

We can smooth the sliding surfaces to lessen friction. When two surfaces slide against one another, friction arises. The main source of friction is the microscopic interlocking mechanism. We can minimise the amount of friction between the surfaces by decreasing this interlocking.

Read Also: How To Clean A Clogged Drain

2. Application of Lubricants

Coat the contacting surfaces with the appropriate lubricant. By minimising direct material contact, this produces a thin layer that lowers friction.It may guarantee smooth sliding in addition to lowering heat generation. The majority of lubricants are paste-like, semi-solid substances that lower dry sliding friction.

3.Ball bearings and rollers

By enabling smooth rolling motion rather than sliding, the use of ball bearings or rollers between interacting surfaces can greatly minimise friction.

Read Also: How To Do Basic Home Carpentry

4. Minimize surface contact

Reducing surface contact when sliding can help to lower friction. Is it feasible, though?

Yes, by using magnetic levitation or applying the same polarity to both surfaces, we can minimise touch.

The idea of magnetic levitation, or “maglev” trains, is to reduce friction while increasing speed and travel time.

5. Instead of using dry friction, use fluid friction since fluid surfaces provide less friction than solid ones

For this reason, compared to cars, aircraft are able to travel at tremendous speeds. Furthermore, we are effectively transforming dry friction into fluid friction when we apply lubricants or oil to surfaces.

Read Also: How to get Wet Smell out of Carpet (All You need to Know)

There’s one more way to cut down on friction. Though theoretically feasible, this may not be feasible in practice. The friction that exists between vehicles and the road, between our shoes and the ground, etc., would disappear if the Earth’s gravitational force were eliminated. Alternatively, the friction reduces even if the gravitational pull is lessened. This is theory only; it won’t actually happen!

6. Material coating

A protective layer that lowers friction can be applied by using specialised coatings like polymers or dry film lubricants.

Read Also: How To Unclog A Double Kitchen Sink

Conclusion

Reducing surface friction is essential for maximising effectiveness, lifespan, and performance in a variety of applications. Frictional forces can be reduced by using these techniques mentioned above. The efficiency of friction reduction techniques is further increased by routine maintenance and environmental considerations. Industries can preserve energy, lessen wear and tear, increase the overall functionality of surfaces in touch, and increase the dependability of mechanical systems by combining these strategies.

FAQs & Answers

1. What is friction, and why should surfaces be made less of it?

A force that opposes the relative motion or tendency of two surfaces in touch to move in that way is known as friction. In order to maximise mechanical system performance, minimise wear and tear, improve energy efficiency, and promote efficiency, friction on surfaces must be reduced.

2. Does minimising friction need routine maintenance?

Unquestionably. Frequent upkeep and cleaning stop dirt and debris from building up, which can cause friction to grow. Surfaces that are kept up properly perform at their best and last longer.

3.Are techniques for reducing friction always applicable, or do they rely on particular situations?

The choice of friction reduction techniques frequently depends on the particular application, materials involved, and operating conditions, even if some techniques, such lubrication and surface polishing, have broad applicability.